Custom Molded Gaskets for Packaging Equipment

Published November 2025

Introduction

Molded silicone gaskets play a critical role in keeping packaging equipment running efficiently and help to create an optimally sealed package for your product. They are engineered sealing components designed to withstand intermittent compression under high heat while still maintaining their elasticity and shape. In the packaging environment, where time is everything, a dependable seal prevents leaks, contamination, and premature wear.

At Inter-Tech Supplies, molded silicone gaskets are one of our core specialties. For nearly 40 years, we’ve been producing custom gaskets that deliver consistent, repeatable performance for rollstock, HFFS, tray sealing, blister packaging, medical applications, and more.

What are Molded Silicone Gaskets and Why They Matter in Packaging?

Molded silicone gaskets are essential sealing components in the packaging industry. They provide reliable sealing performance for rollstock, tray sealing, blister packaging, and other applications where heat, pressure, and hygiene are critical.

Benefits of Molded Silicone Gaskets in Packaging Equipment

The benefits of molded silicone gaskets in packaging equipment include heat resistance, durability, and food-safe performance. Silicone’s material advantages make it ideal for the demanding environments found in food, medical, and industrial packaging. Key benefits include:

- High temperature resistance: Stands up to intermittent heat cycling and the elevated temperatures of sealing processes.

- Moisture: Performs reliably through repeated sanitation and washdowns.

- Durability & longevity: Retains flexibility and structural integrity even under long-term machine cycling.

- Food-grade & compliant options: All of our silicone gaskets are manufactured using FDA-compliant material, suited for the food and medical packaging industries.

- Exceptional design flexibility: With in-house reverse engineering and gasket design assistance, our manufacturing capabilities can accommodate aftermarket and prototyping projects with ease.

Advantages of Custom Silicone Gaskets for Sealing Applications

One of Inter-Tech’s strongest differentiators is our industry knowledge, giving packaging customers confidence that every gasket will install, seal, and perform exactly as intended and This level of precision helps:

- Improve sealing consistency

- Reduce wear on gaskets, tooling, and seal plates

- Minimize scrap and rework

- Maintain stable sealing performance across long production runs

Whether your machinery is Multivac™, or a fully customized line, our gaskets are engineered to fit perfectly every time.

Customization Options for Your Molded Silicone Gaskets

Every packaging line is different, so we build each gasket around your specific requirements. Customer-guided customization includes:

- Durometer Selection & Testing: Choose the hardness that best matches your sealing application. We offer various durometers, along with durometer testing for validation.

- Surface Texture Options: Smooth seal, aggressive grid and standard grid textures are all specifically designed to meet the needs of your machine, film type and specific sealing application.

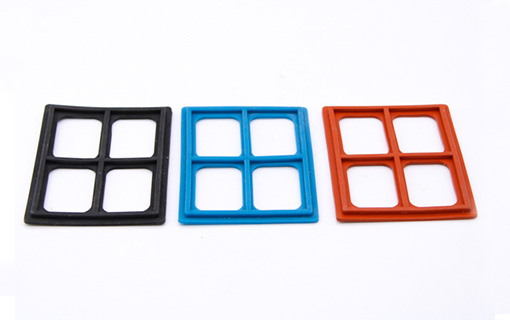

- Color-Coding for Plant Organization: Pigmented silicone options help customers visually identify gasket styles, and color coordinate various durometers across the production floor. Ideal for large plants and multi-line facilities.

- Collaborative Engineering Support: Our team walks you through the design process, offering hands-on guidance, prototype feedback, and engineering insights to ensure the gasket is exactly right before it goes to production.

Inventory Programs for High-Usage Customers

For customers who rely on regular gasket replacements, Inter-Tech can stock dedicated inventory specific to your models, eliminating lead times and ensuring immediate shipment when you need it most. This program helps high-volume facilities maintain uptime and avoid costly production interruptions.

Molded Silicone Gasket Types We Manufacture

Inter-Tech Supplies manufactures molded silicone gaskets for virtually all packaging formats, including:

- Form-fill-seal (HFFS) gaskets

- Tray sealer gaskets

- Blister and thermoforming gaskets

- Assorted T-Profiles

- Medical and cleanroom-grade sealing profiles

- Various silicone parts

And when your project requires tooling, we also fabricate seal plates, seal grids and precision-machined components that pair perfectly with your custom gasket design. Whether you need gaskets, tooling, repairs, Teflon coating, or laser cutting, we are here for you.

Why Packaging Manufacturers Choose Inter-Tech Supplies

For four decades, Inter-Tech has been a trusted partner to the food, medical and packaging industries. Customers choose us because:

- We manufacture high-performance molded silicone gaskets engineered for demanding sealing environments.

- We offer fast turnaround, in-house molding, and strict quality control.

- We accommodate flexible customization including durometer, texture, color, size, and specialty profiles.

- Our team delivers true customer support and technical guidance, not just parts.

- We help reduce machine downtime with reliable seals and customer-specific inventory programs.

Ready to Improve Your Sealing Performance?

If you’re looking for reliable molded silicone gaskets that enhance machine uptime, sealing quality, and long-term performance, our team is ready to help.

Contact Inter-Tech Supplies today for a free quote on your custom molded silicone gasket requirements.

Need a Quote or Want to Discuss Your Application?

We’re here to help. Contact us today to learn how we can improve your packaging line with custom molded silicone gaskets.

Let’s get your equipment running cleaner, faster, and longer.

100% In-House Design And Manufacturing!

We can create your gasket from a sample or a CAD drawing.