Seal Plate and Die Repair Services

Precision Tooling Repair Services for Packaging Equipment

Inter-Tech Supplies provides seal plate and die repair services for packaging equipment, helping manufacturers restore performance, extend tooling life, and minimize costly downtime. Our precision repair process ensures sealing surfaces, tolerances, and alignment meet original or improved specifications. With our in-house machining and tooling expertise, we repair worn, damaged, or out-of-spec seal plates and dies used in a wide range of packaging applications.

With 40 years of experience in packaging tooling repairs including seal plate repair and the refurbishing of seal and heat plates, we offer free quotes with fast turn-around times.

Seal Plate and Die Repair Services You Can Rely On

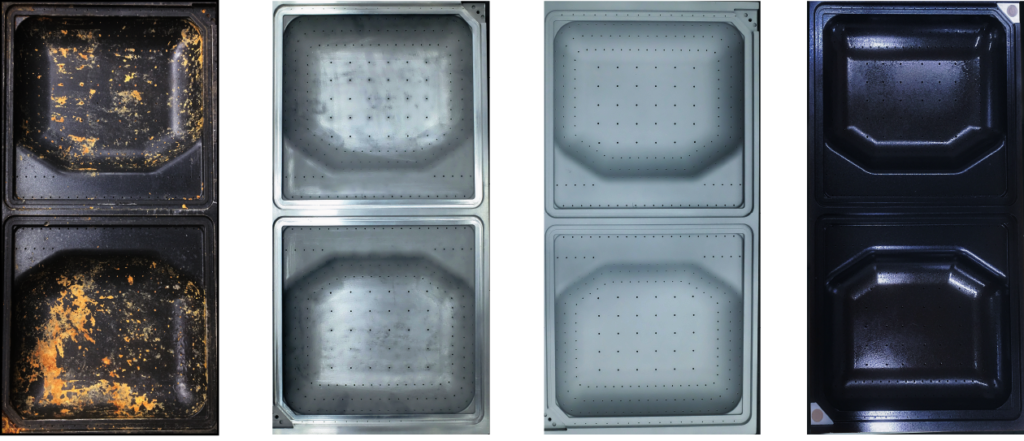

Seal plates and dies play a critical role in forming, sealing, and maintaining package integrity. Over time, heat exposure, wear, and repeated cycles can lead to uneven sealing, product defects, or machine inefficiencies.

Our seal plate and die repair services are designed to restore tooling accuracy and reliability while reducing the need for full replacement.

Our repair capabilities include:

- Surface reconditioning and refinishing

- Precision machining, sandblasting, and grinding

- Flatness and tolerance correction

- Edge and profile restoration

- Heat-affected wear repair

- Functional testing and inspection

Common tooling we repair includes:

- Seal plates

- Sealing dies

- Forming dies

- Packaging trays

- Cutting assemblies

- Face plates

Duplicate Seal Plates

Prevent downtime: Send your seal plate for repair and request a quote for a duplicate. This limits your machines downtime with our quick turnaround, ensuring continuous operation.

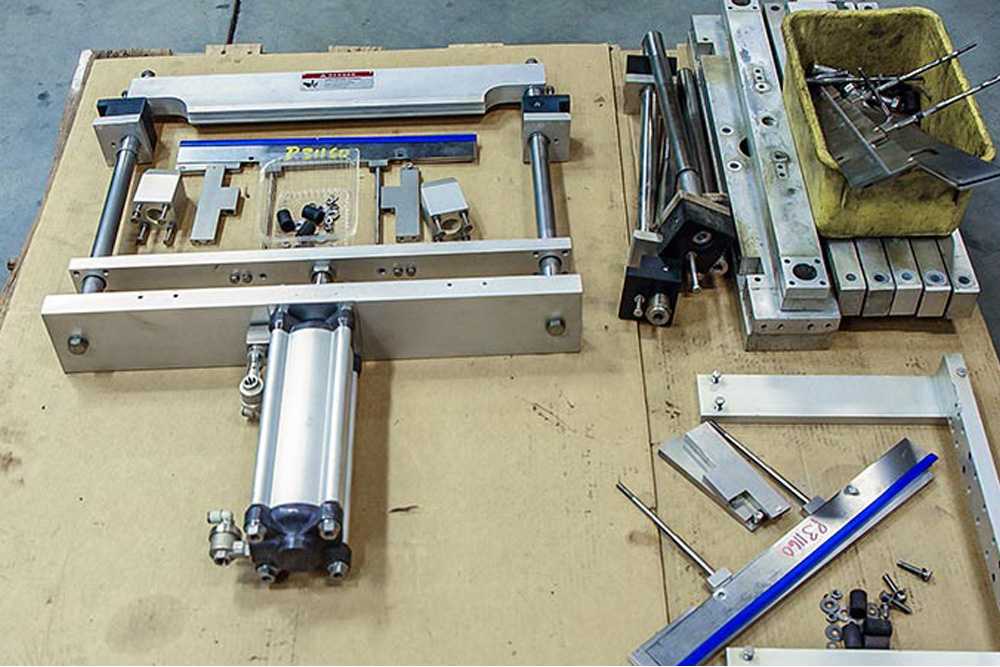

Forming & Sealing Die Overhaul

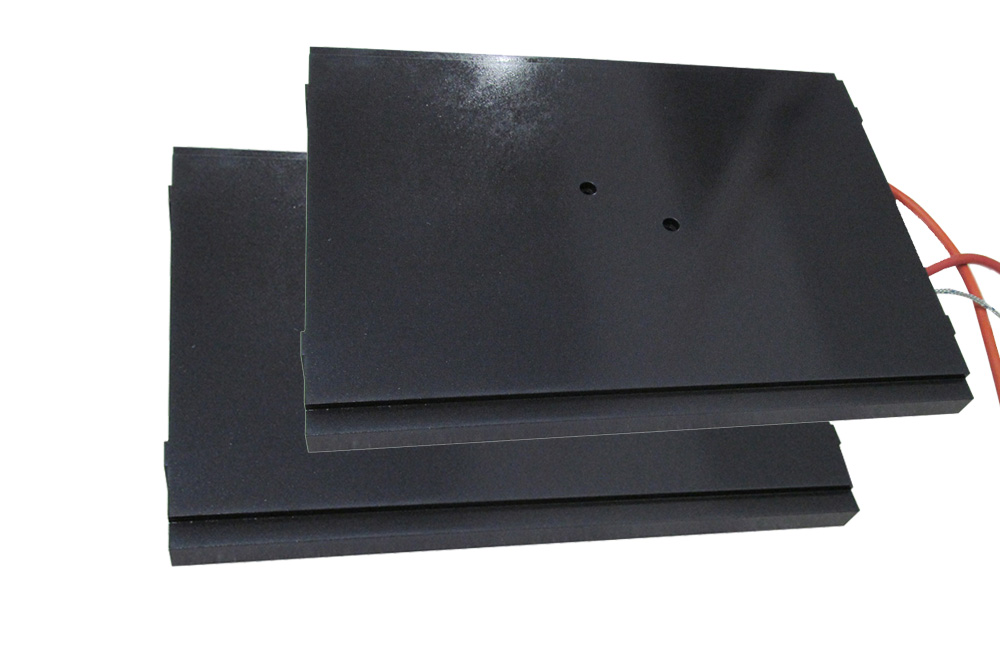

At Inter-Tech Supplies, we offer our specialized overhaul and refurbishing services for heating and sealing plates across a broad spectrum of packaging machinery. Our Teflon coating services and comprehensive repairs are designed to meet the needs of any packaging operation, ensuring that all work meets or exceeds OEM standards. Our standard seal plate overhaul package includes:

- Thorough Cleaning

- Welding – as necessary

- Machining

- Teflon coating with fast turnaround

- Installation of new heating elements – includes thermocouple and wiring

- All repairs are bench-tested before shipping

Sealing Plate Overhaul

Check out our brochure on our seal plate repair services below with a free download.

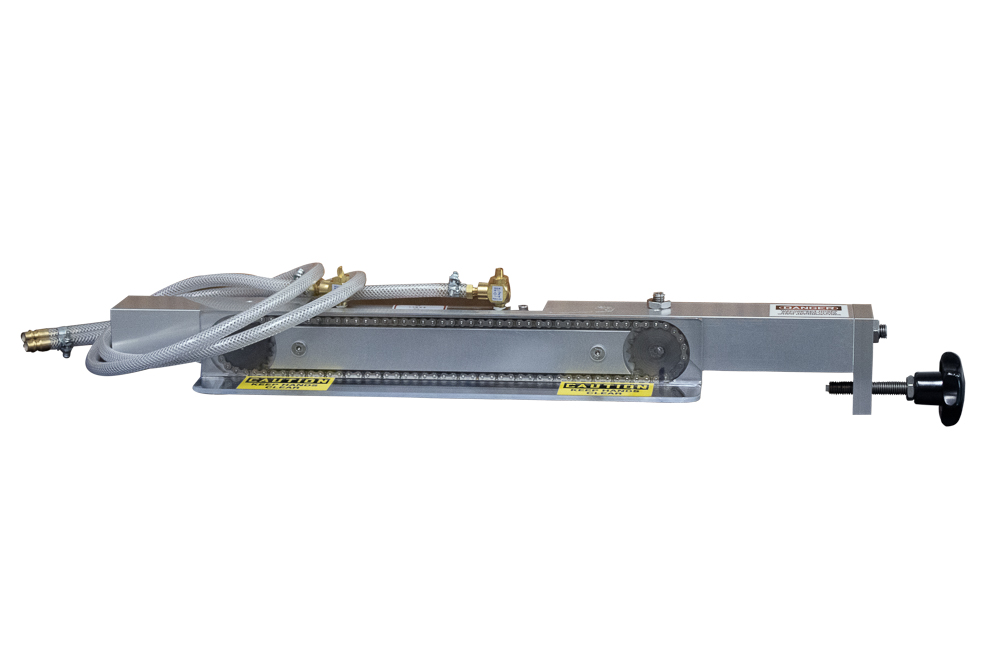

Cutting Assemblies Repair Services

Repair and refurbishing of cutting assemblies, units, and components of various styles from flying crosscut knife units to guillotine-style cutting units and punches. We repair or replace all necessary parts to OEM specifications. We also manufacture new cutting units.

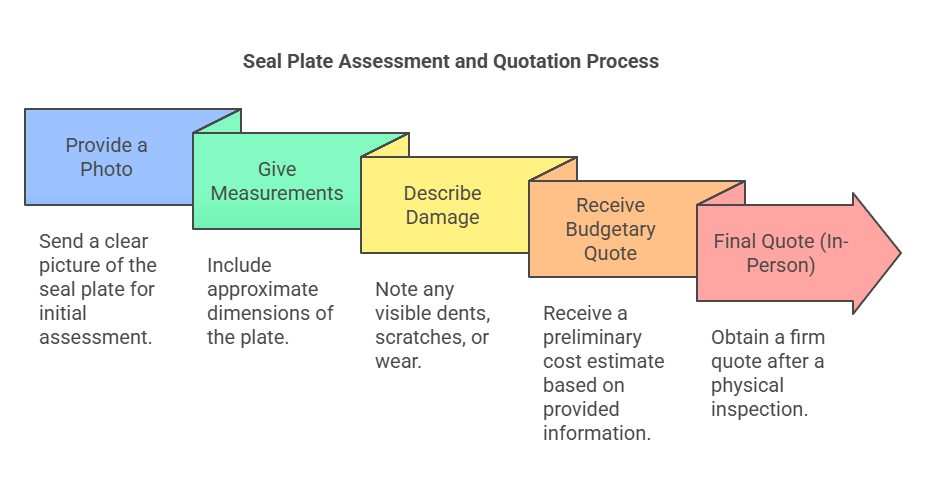

Interested in a Budgetary Quote for Seal Plate Repair?

Are you interested in a free quote for your seal plate and tooling repair? Below is all the information we need to get you your free quote! Click the button below or call us at 1-800-722-7761.

FAQ: Commonly Asked Questions with Answers

What are seal plate and die repair services?

Seal plate and die repair services restore worn or damaged sealing and forming tooling used in packaging equipment by correcting tolerances, surface finishes, and functional performance.

When should seal plates or dies be repaired instead of replaced?

Seal plates and dies should be repaired when wear, heat exposure, or surface damage affects sealing performance but the tooling structure remains intact and repairable.

What types of packaging equipment use seal plates and dies?

Seal plates and dies are commonly used in form-fill-seal machines, tray sealers, and other packaging systems that rely on precise sealing and forming operations.

Can custom or proprietary seal plates be repaired?

Custom and proprietary seal plates and dies can often be repaired using precision machining based on drawings, samples, or application requirements.

How do seal plate and die repairs improve packaging performance?

Properly repaired tooling improves seal consistency, reduces scrap, minimizes downtime, and helps maintain optimal machine efficiency.