TOOLING FABRICATION

FABRICATION OF DIE COMPONENTS, SEAL PLATES, & DIVIDER SETS

We specialize in custom machining die tooling and components for Multivac™ and various other packaging equipment including complete die sets, seal plates, divider sets, special inserts, heating plates, forming and sealing bottoms, or other special components. We offer engineering and design services for new packaging ideas and tooling requirements. From concept to manufacturing we partner with you to streamline production of new package and tooling requirements.

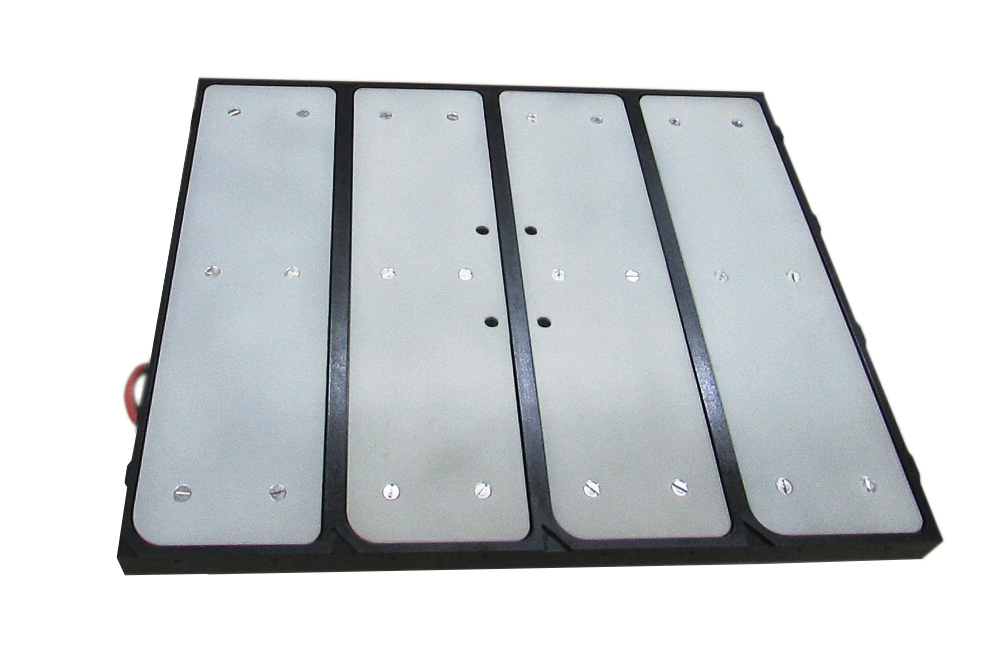

Replacement Seal Plates

Total Sealing and Forming Plate

Send your damaged seal plate for repair or recoating, and Minimize downtime with a duplicate seal plate. Let us craft a precise duplicate for uninterrupted performance. Ready to ensure continuous productivity? Contact us now to create your duplicate seal plate.

Perimeter Seal – Faceplates

Perimeter seal face plates provide maintenance teams the advantage of easily changing out the Teflon-coated plates without rebuilding the seal plate. We offer these face plates in either bonded aluminum or G10 material.

Perimeter Seal Plates

We manufacture total perimeter seal plates, also available with bonded aluminum or G10 material, but include replacement heaters and thermocouples.

Other Fabrication Services

Replacement Rollers and Shafts

Fabrication of replacement rollers, shafts, and special parts for Multivac™ equipment.

Custom Manufacturing of Cutting Units

Inquire about guillotine or cross-cut Knife assemblies.

Reliable Service and Short Lead Times

Reliable service with fast turnaround times for repair of worn or damaged die components, including welding and machining.

Tooling Examples

Complete Die Sets

Replacing a complete die set in vacuum packaging equipment serves several critical purposes, enhancing both the efficiency and the quality of the packaging process. Whether you need to replace old dies or adapt to new packaging requirements, Inter-Tech’s CNC department has you covered. Call today and speak with our team.

- Forming Top

- Forming Bottom

- Sealing Top

- Sealing Bottom

Forming and Sealing Die Bottoms

The forming die is responsible for shaping the flat packaging material. It creates a cavity or pocket with the appropriate dimensions and shape for holding the product. We can customize forming and sealing dies to specific packaging requirements such as pouch size, shape, and design.

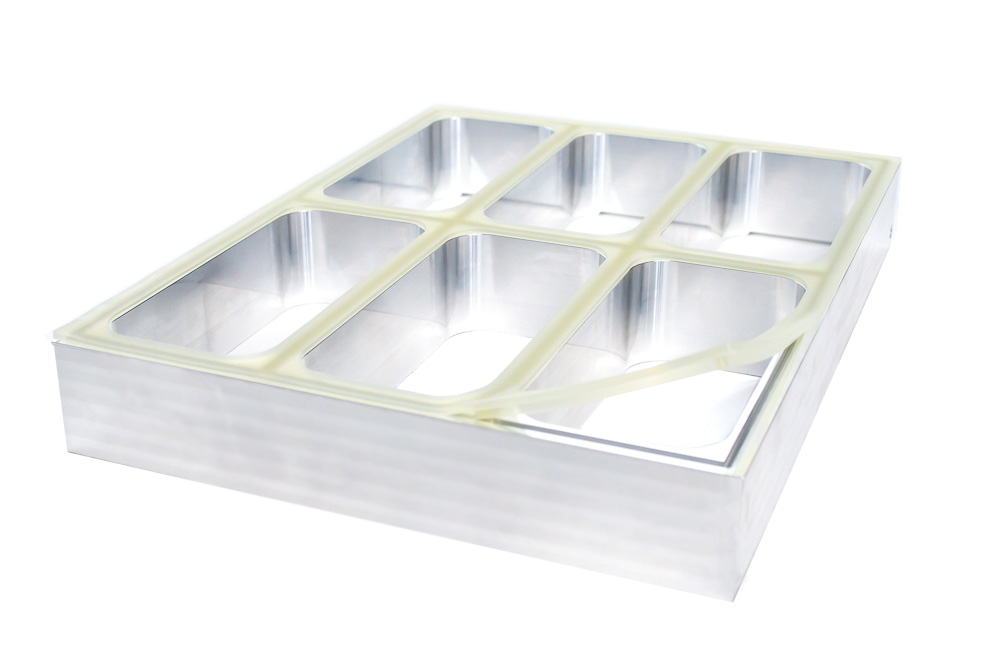

Complete Divider Set and Components

A Complete Divider set offers a cost-effective packaging modification for facilities looking to expand their existing equipment. The divider set is engineered to perfectly match your machine’s web width and cut-off while offering a customizable grid and pocket depth to match the product you are packaging.

- Forming Insert

- Sealing Grid

- Custom Engineered Gasket

- Radius Plates

Seal Grid with Custom Sealing Gasket

Choosing Inter-Tech for your tooling fabrication and gasket manufacturing needs offers unparalleled benefits. Our in-house capabilities ensure rapid turnaround times for new seal grid tooling, complemented by precisely customized gaskets tailored to your specific requirements. Experience the Inter-Tech advantage!

FAQ about our Process

What does Inter-Tech need to design and fabricate custom sealing or forming Dies?

All Fabrication jobs require a CAD drawing to proceed. If a drawing cannot be provided, most jobs will require the tooling to be sent to our facility – allowing our team to accurately measure and quote you on the cost and lead time for your tooling job. Upon approval, we will make a CAD drawing and proceed with production.

How long will the quoting process take?

Typically 2-3 business days. Upon receiving your valued tooling, we will quickly measure and assess the costs, materials, and lead times required to complete your quote.

What are some benefits of filler plates?

- Optimal Seal Integrity

- Flexibility in Packaging Size

- Efficient Resource Utilization

- Improved Air Evacuation

- Prevents Bag Creases and Wrinkles

- Enhanced Operator Safety

- Consistent Production Output

Do You Offer a Rush Service?

Yes. Contact our sales team today to discuss your next expedited order! As a tooling manufacturer, we know our normal lead times are competitive, but we understand that the needs of our customers are critical.

Let us Quote Your Future Tooling Solutions, Today!

Call 1-800-722-7761 or click below for a free quote.